An array of tube cleaners for use in boilers, chillers, evaporators and more.

-

Feature Nylon Shaft While ordering flexible shaft & accessories, each item should be ordered for specific tube / pipes size or size range. Stainless steel inner core ensures our shaft have longest life, resistance to corrosion. To order flexible shaft(s) determine tube I.d. & length of longest tube (s). Order flexible shaft(s) to correspond with tube I.D.(s), & length. Please ask for special or longer length. Steel Shaft - LKS Series It is used for cleaning of tube by transmitting power in terms of rotation form the motor unit to tool head cutter or brush within tube. Inner Core It is flexible wire with multiple wound opposite layer. It is made of high tensile spring steel or stainless steel (as per requirement) and passed through heat treatment processes to make it absolutely vibration free. Outer Casing It is flexible, double interlock, circular rounded, made of galvanized steel strip, Special spring steel lining is provided within outer casing to avoid any friction between inner core & outer casing. Connection One end of shaft with machine end socket is attached to suitable motor and other end is attached to tool end. Steel

Feature Nylon Shaft While ordering flexible shaft & accessories, each item should be ordered for specific tube / pipes size or size range. Stainless steel inner core ensures our shaft have longest life, resistance to corrosion. To order flexible shaft(s) determine tube I.d. & length of longest tube (s). Order flexible shaft(s) to correspond with tube I.D.(s), & length. Please ask for special or longer length. Steel Shaft - LKS Series It is used for cleaning of tube by transmitting power in terms of rotation form the motor unit to tool head cutter or brush within tube. Inner Core It is flexible wire with multiple wound opposite layer. It is made of high tensile spring steel or stainless steel (as per requirement) and passed through heat treatment processes to make it absolutely vibration free. Outer Casing It is flexible, double interlock, circular rounded, made of galvanized steel strip, Special spring steel lining is provided within outer casing to avoid any friction between inner core & outer casing. Connection One end of shaft with machine end socket is attached to suitable motor and other end is attached to tool end. Steel -

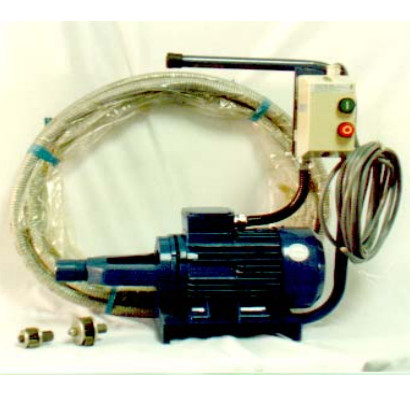

Feature LKS has design an electric driven shaft with a simultaneous water flush tube- cleaning machine especially for water tube boiler. This machine is capable to clean the straight, bend and tee tube. The machine has successfully done a cleaning at site for Babcock boiler, Vickers Hoskins boiler, Fraser I&II boiler, Yoshimine boiler, Maxitherm boiler and etc.

Feature LKS has design an electric driven shaft with a simultaneous water flush tube- cleaning machine especially for water tube boiler. This machine is capable to clean the straight, bend and tee tube. The machine has successfully done a cleaning at site for Babcock boiler, Vickers Hoskins boiler, Fraser I&II boiler, Yoshimine boiler, Maxitherm boiler and etc. -

Feature MODEL TCS-PORTO Chiller Tube Cleaning System is the most common system for cleaning chillers by users to whom size and portability is paramount. Contents: 'PORTO' - Portable Tube Cleaner-1 PFS - 500 - 140 Flexible Shafts - 2 Nylon Brushes (specify size) - 25 Single Direction Foot Switch - 1 Repair Kit for Flexible Shaft PFS - 500 Consisting of: 4 Drives End Couplings, 4 Tool End Couplings, 1 Shaft Repair Tool with Hammer, 1 Flexible Shaft Lubricator and 2 Bottles of Lubricant.

Feature MODEL TCS-PORTO Chiller Tube Cleaning System is the most common system for cleaning chillers by users to whom size and portability is paramount. Contents: 'PORTO' - Portable Tube Cleaner-1 PFS - 500 - 140 Flexible Shafts - 2 Nylon Brushes (specify size) - 25 Single Direction Foot Switch - 1 Repair Kit for Flexible Shaft PFS - 500 Consisting of: 4 Drives End Couplings, 4 Tool End Couplings, 1 Shaft Repair Tool with Hammer, 1 Flexible Shaft Lubricator and 2 Bottles of Lubricant. -

Feature This LKS Second generation of tube cleaner is also an electrical driven tube-cleaning machine and is specially designed for cleaning a boiler straight tube, chillers, condensers, evaporators, absorption machines and heat exchanger. This electrical driven cleaning machine is suitable for tubes size is in between 11⁄4 “ “ to 4” internal diameter.

Feature This LKS Second generation of tube cleaner is also an electrical driven tube-cleaning machine and is specially designed for cleaning a boiler straight tube, chillers, condensers, evaporators, absorption machines and heat exchanger. This electrical driven cleaning machine is suitable for tubes size is in between 11⁄4 “ “ to 4” internal diameter. -

Feature The LKS electrical driven tube-cleaning machine is especially design for cleaning tube, juice heater and vacuum pan tubes. This TCM model is also a economy tube cleaning machine which is an electrical type and is suitable for all type of boiler provided the tubes size is in between 1⁄2“ to 4” internal diameter. The smallest bending radius is 250mm at 180O degree.

Feature The LKS electrical driven tube-cleaning machine is especially design for cleaning tube, juice heater and vacuum pan tubes. This TCM model is also a economy tube cleaning machine which is an electrical type and is suitable for all type of boiler provided the tubes size is in between 1⁄2“ to 4” internal diameter. The smallest bending radius is 250mm at 180O degree. -

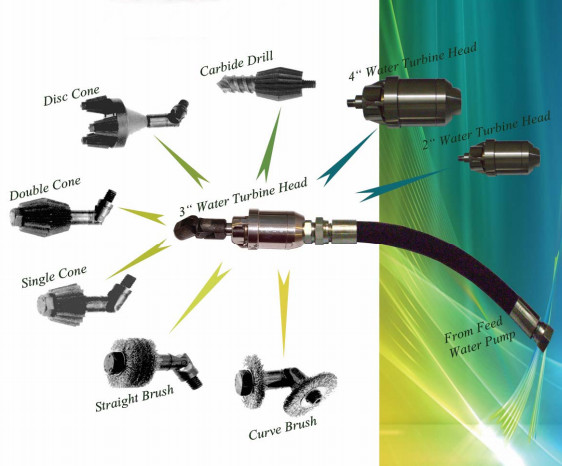

Feature LKS has developed a new generation tube cleaner with a water/air driven power. This tube cleaner are especially design based on market requirement after a market study. The tube cleaner is design for cleaning tube Boiler, Heat exchanger, condensers, super heaters, services pipeline and any applicable tube. This TCM-V3 design for reliability and solve the flexible shaft snap problem. It is suitable for tubes size is 3⁄4” to 4” internal diameter. The bending radius is from 230 to 520mm at 180◦ degree.

Feature LKS has developed a new generation tube cleaner with a water/air driven power. This tube cleaner are especially design based on market requirement after a market study. The tube cleaner is design for cleaning tube Boiler, Heat exchanger, condensers, super heaters, services pipeline and any applicable tube. This TCM-V3 design for reliability and solve the flexible shaft snap problem. It is suitable for tubes size is 3⁄4” to 4” internal diameter. The bending radius is from 230 to 520mm at 180◦ degree.