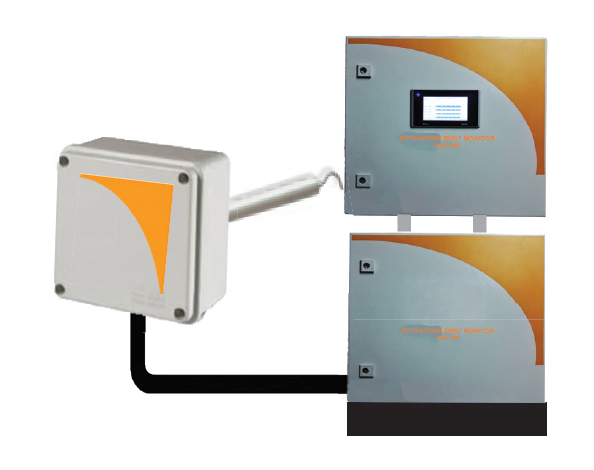

- In-situ zeroing and span calibration

- Automatic gain control function and temperature compensation

- Smart appearance, easy installation, convenient disassembly

- Without background light influence

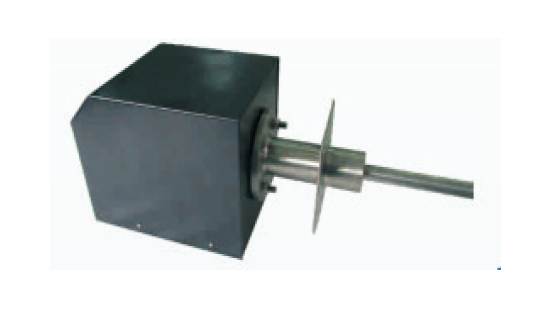

- Palm Oil Mill

- Paper Mill

- Gas Fuel Boiler

- Aluminum Plant

- Steel Plant

- Cement Plant

- Steel & Iron Plant