- Combination of transmittance and scattered light measurement

- For very low to high dust concentrations

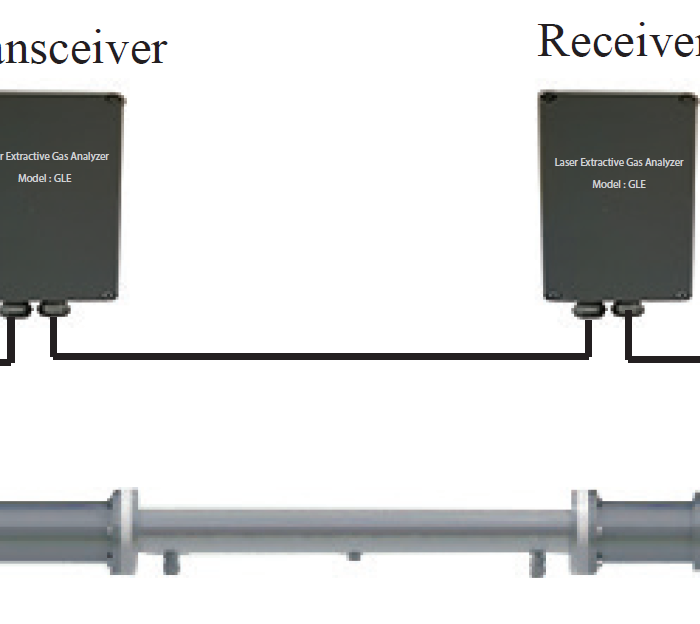

- Automatic check of zero and reference point

- Contamination monitoring and compensation on both sides

- Automatic self-alignment

- For medium to large dust diameter

- Suitable for highly fluctuating dust concentrations

- Reliable application due to redundant measurement

- Low maintenance due to self-monitoring function

- Future-proof for decreasing limit values

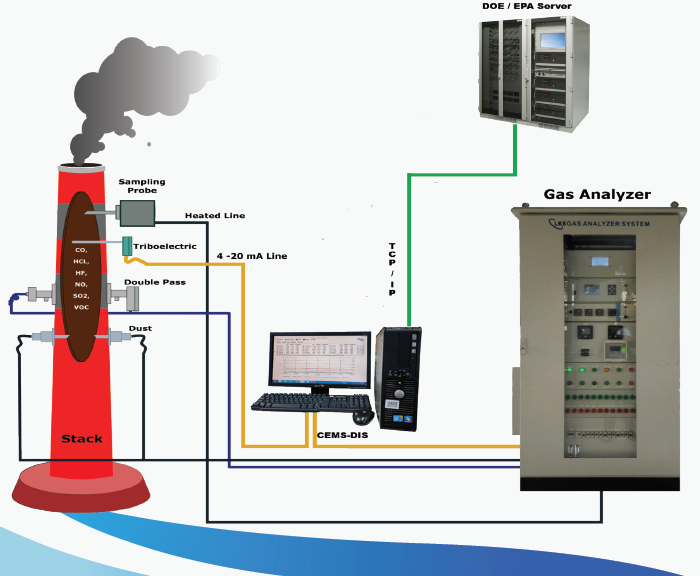

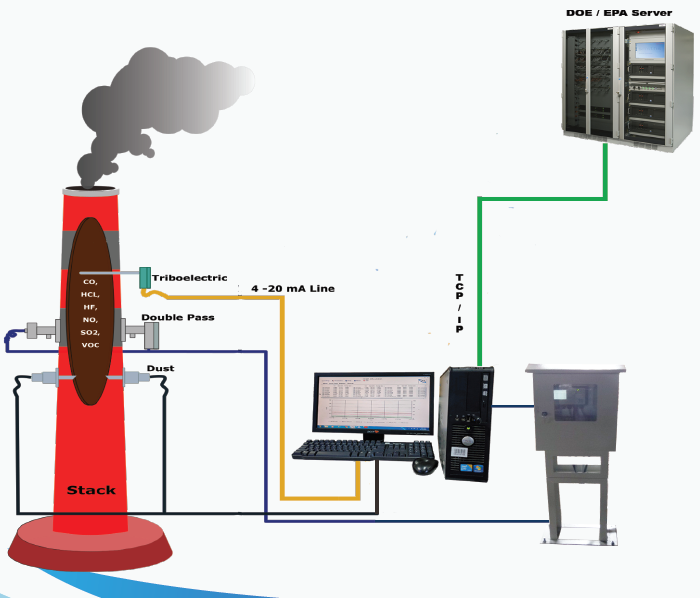

- Solid Fuel Boiler

- Tunnel for Visibility

- Gas Fuel Boiler

- Generator Emission

- Diesel Car Emission

- Rubbish Incinerator