Features

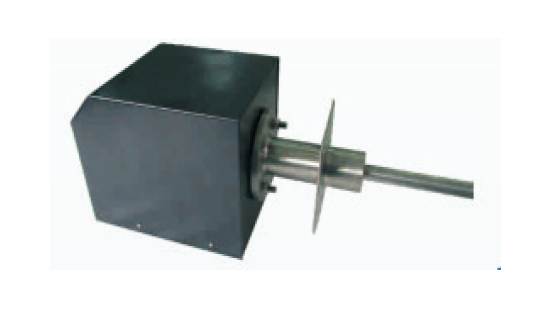

- Detect solid particles with diameters from 0.1μm to 200μm

- For high pressure application up to 1MPa

- Easy to install and adjust

- Easy to maintenance

- Probe Length : 200mm/400mm/600mm/800mm/1000mm

Applications

Cement Plant

- For coal ash and other raw material

- Cement & Concrete product

- For kilns, Air Quality Control System

Ironworks

- For Steel Sintering

- For Casting

- Coke Ovens

Chemical Plant

- For catalyzation

- Smoke Removal

Rubber & Carbon Plant

- Handling Raw Material

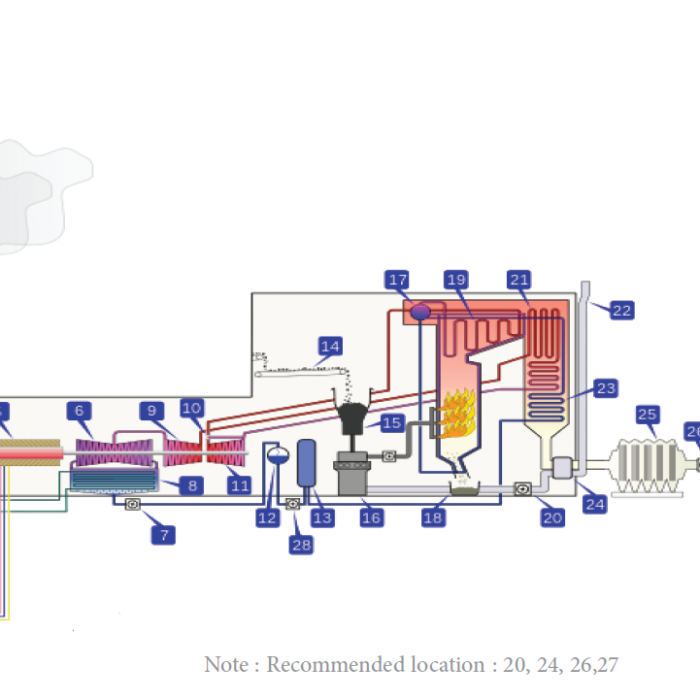

Waste Incinerator Plant

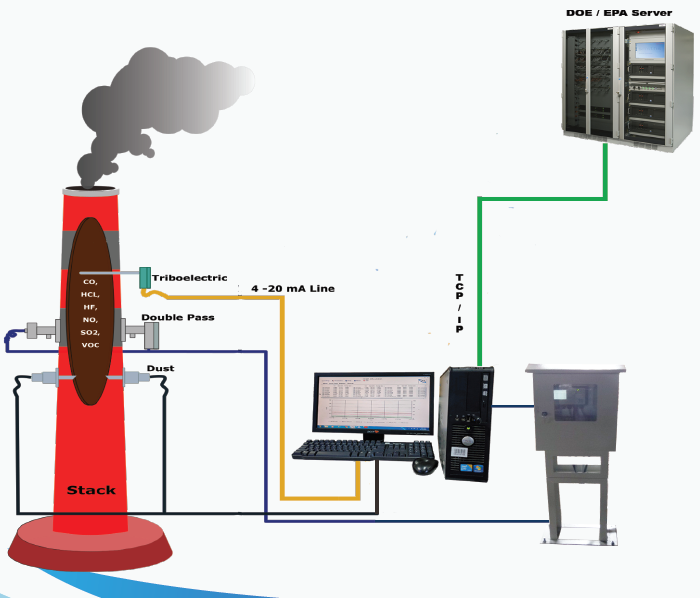

- Monitoring Environmental

- Incinerator